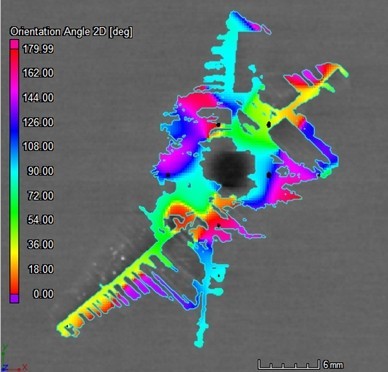

Quantitative Inspection of Complex Composite Aeronautic Parts Using Advanced X-ray Techniques – this project focuses on progress in characterisation, simulation and modelling of aircraft parts.

Project description

During last decades in the aerospace, a clear trend of continuous intensive industrial research of new, tailor-made materials has formed, which can be used for manufacturing of cheap, functional, highly integrated and light parts. Driving force of this trend is big demand of airlines and aircraft operators for effectivity, ecology, safety and comfort of passengers.

State-of-the-art composite materials, especially polymers with carbon reinforcement (CFRP) are most promissing materials which can satisfy this demand from designers of future aircrafts (fuselage, horizontal stabilisers, parts of drive system). Designers of the next generation aircrafts plan to use more than 50% parts made of composite. However, with increasing use of composite materials, requirements of non-destructive testing rise.

This Quicom project connects together 12 partners from 6 European countries – 6 research partners, 3 large companies, 2 middle-sized companies and association EASN (The European Aeronautics Science Network). The target is to create a network of X-ray technologies, software, applications and specialists for composite materials who would collaborate on a reliable, fully 3-dimensional inspection of aircraft parts. There is no single group in Europe able to complete this project individually, or no single project partner able to complete one single package of tasks individually.

Start of the project is October 2012, completion is anticipated in September 2015. Further details on Quicom project are here.

Quicom is funded from the 7th frame programme.

Čeština

Čeština  English

English