LA composite, s.r.o.

LA composite, s.r.o. (company limited) was founded on 10 August 1995 as joint venture of companies Letov, a.s. and ATG, s.r.o.. Later on, ATG, s.r.o. acquired the Letov's share and became an exclusive owner of LA composite.

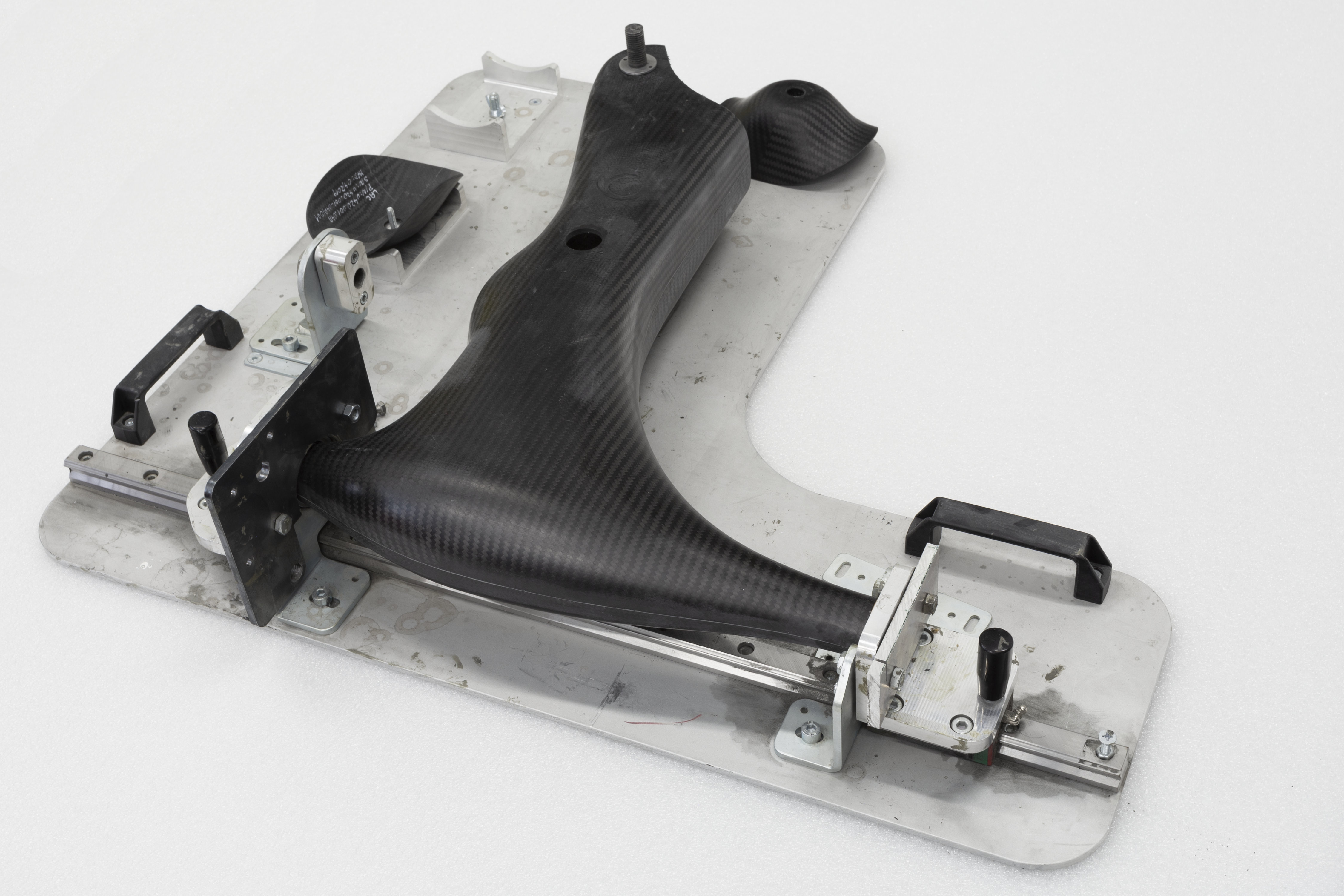

Since then, we have been continuing in the long-standing tradition of manufacturing of composite, sandwich and bonded structures for aerospace industry. Meanwhile, our range of product expanded into the terrestrial transport industry (railway vehicles, automotive) and into other applications (yachts, textile industry etc).

We offer our customers wide range of complex services from design up to serial production of parts. Our key technology is lay-up of prepreg lay-up into the mould and curing in autoclave or oven.

Our key technology is lay-up of prepreg plies into the mould and curing in autoclave or, in case of sandwiches, in oven.

We work with various resin systems such as Epoxy, Fenol and BMI.

Production resources

- Prepreg cutting - computer controlled cutting machines

- Lay-up

- Air conditioned clean rooms

- Laser projectors for precise positioning of the plies and cores

- Curing

- Numerically controled Autoclave 1 - ø 2,3m x 7m, max. pressure 7 bars, max. temperature 200°C

- Numerically controled Autoclave 2 - ø 2,6m x 9m, max. pressure 10 bars, max. temperature 200°C, 32 channels data aquisition system, manufacturer Scholz

- Oven – 3,0 x 2,5 x 7,0 m, max. temperature 300°C, atmospheric pressure

- 5 axis CNC suitable for machining of reinforced plastics

- Material storage - freezing box 180 cbm

Čeština

Čeština  English

English