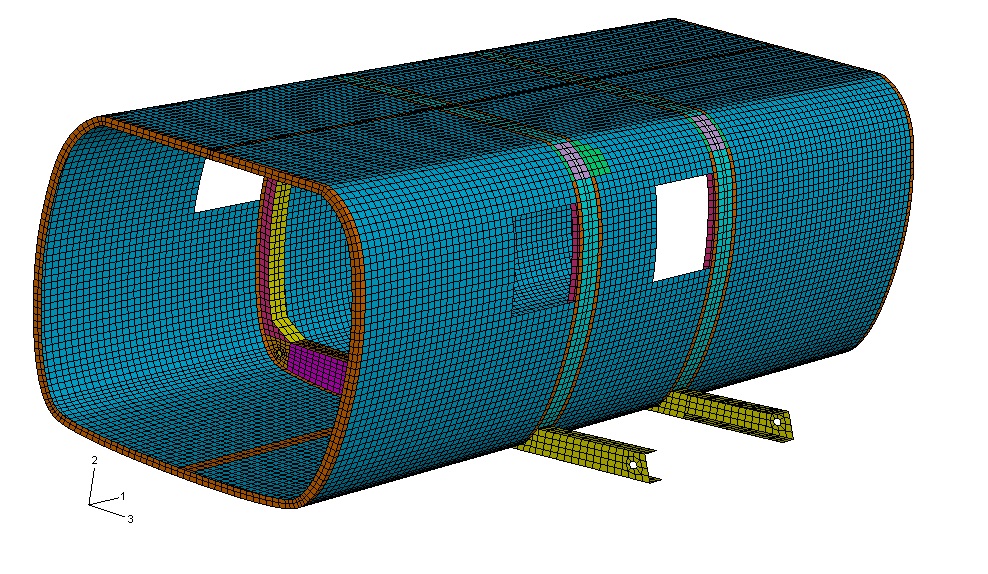

Parts of the projects were: structural design of fuselage, strength analyses according to FAR 23, technology development and engineering, manufacturing of prototypes and tests performed according to requirements for certification of primary structures made of composite materials.

Project description

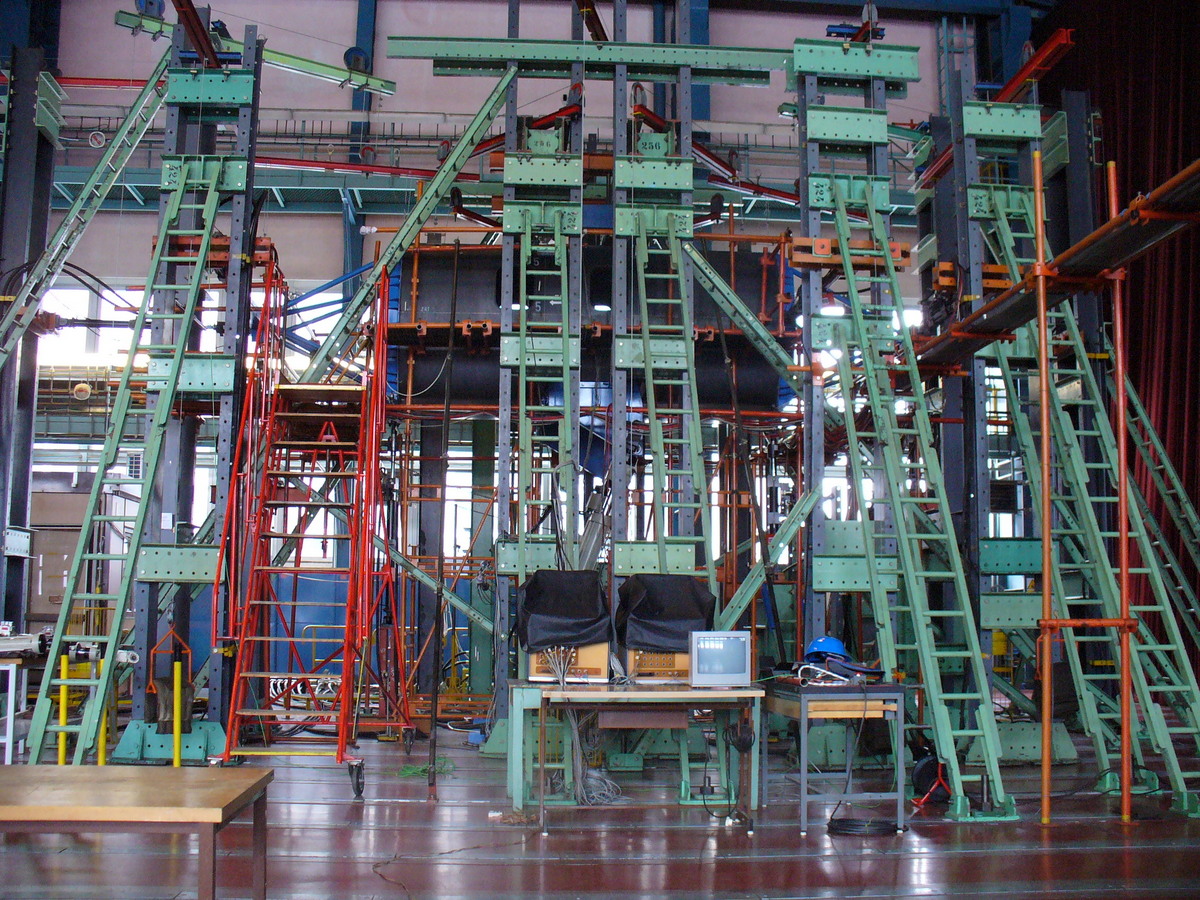

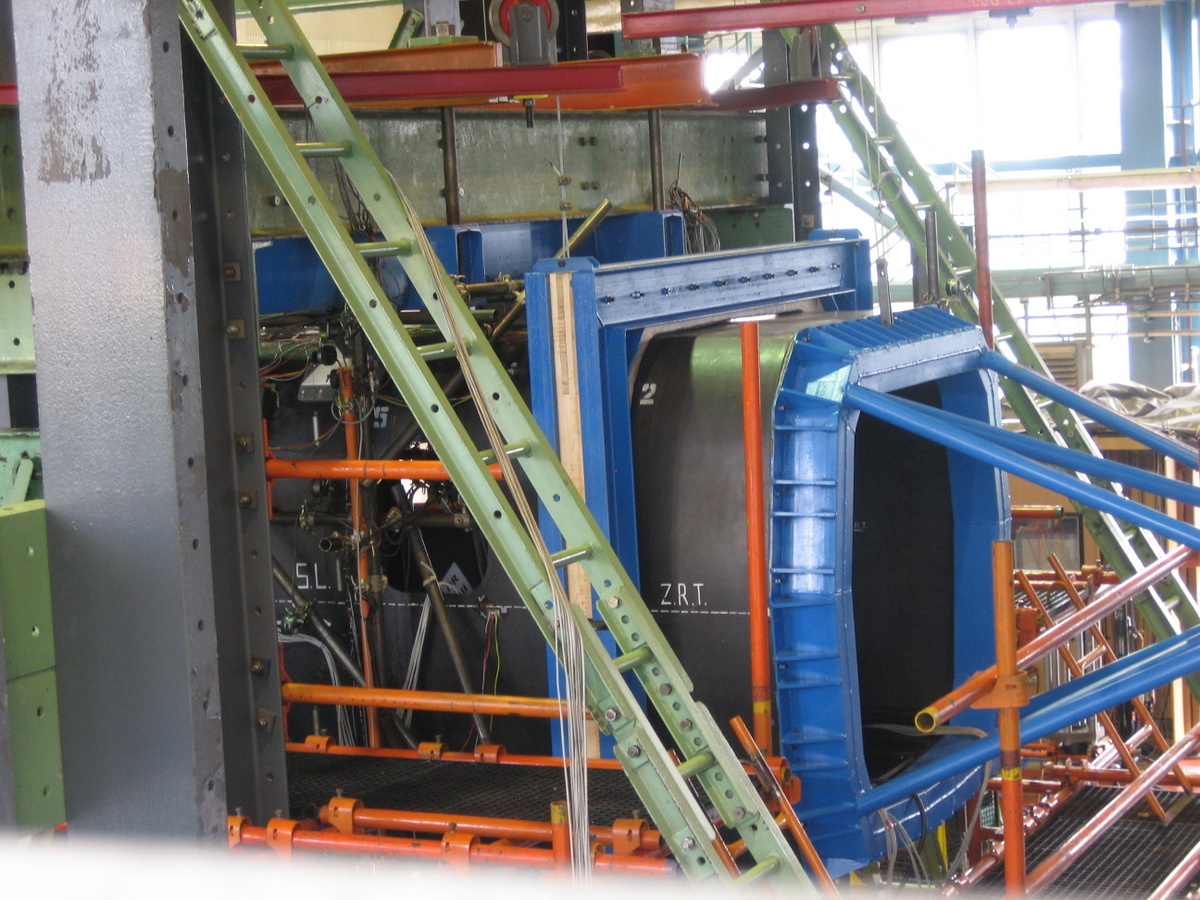

This small aircraft is defined for maximum 9 passengers + 1 crew member, maximum take-off weight is 5 670 kg. The composition of project investigators coresponded to this target. Tests have been performed fully in accordance with philosophy Damage Tolerance and defect non-proliferation has been proved with the combined test.

The project ended very successfully. Company Evektor, partner of the project, performed comparison of the composite fuselage with a comparable metallic fuselage. The result is that a composite fuselage is by 20% lighter, consists of by 85% less parts and its manufacturing needs by 16% less working hours than a comparable metallic fuselage.

LA composite was the general investigator, co-investigators were Vyzkumny a zkusebni letecky ustav (Research and Test Institute for Aviation), Evektor-Aerotechnik and ATG.

The project is financed by contribution of Ministry of Industry and Commerce, Czech Republic.

Čeština

Čeština  English

English